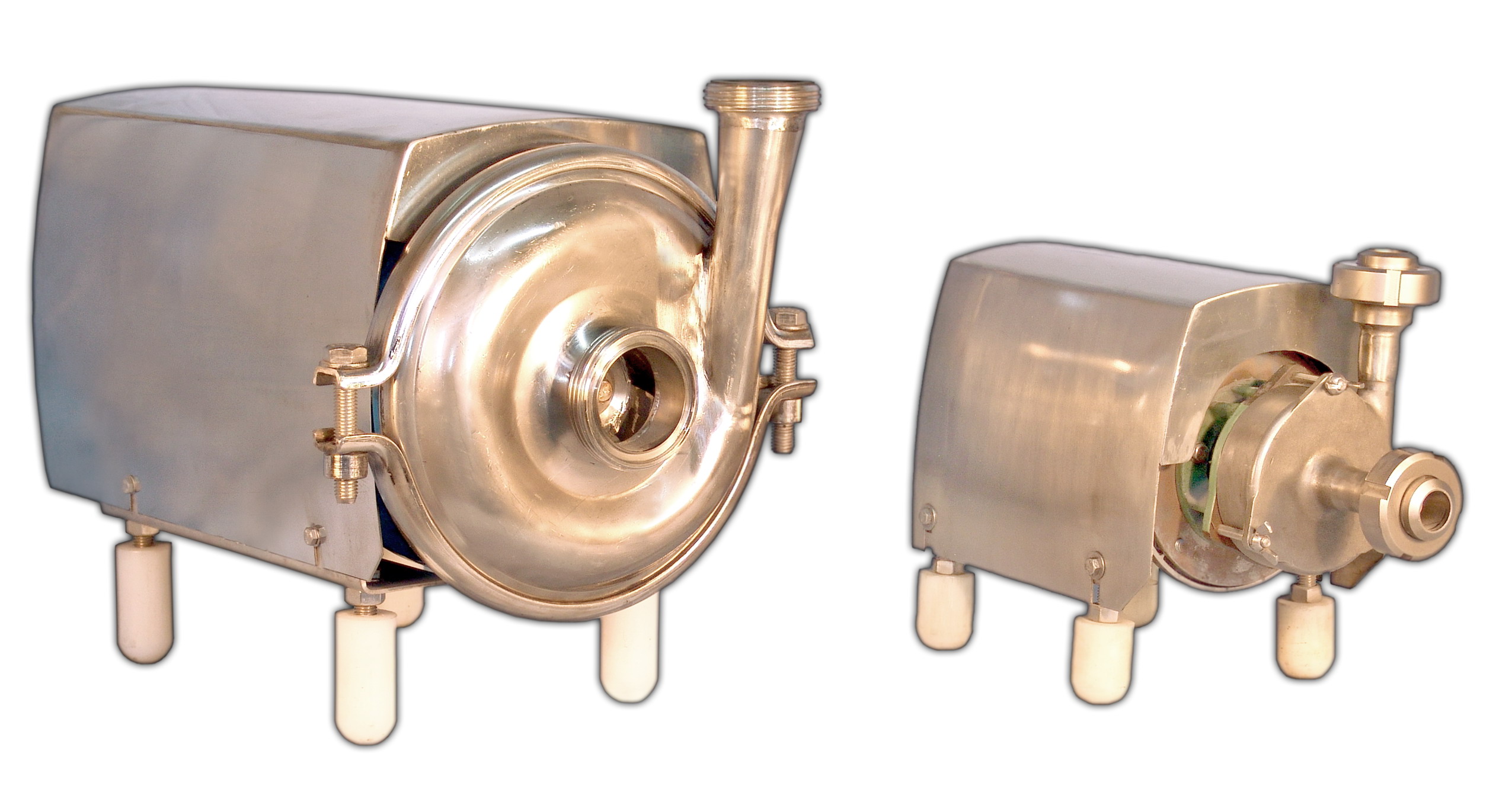

Overall, the fluid transfer in the dairy factories is done by the pumps.

Accordingly, centrifugal pumps are widely used in dairy industry.

The centrifugal pumps consist of primarily of an impeller rotating in a pump casing, a delivery chamber and an electric drive.

The impeller generally consist of a number of vanes that, together with the casing, form closed channels for the liquid.

The liquid enters the pump axially at the center of the casing and is carried round by the vanes at a speed that becomes progressively higher as the liquid is forced outwards along the vanes. It is the then discharged into the delivery chamber of the pump casing with a high kinetic energy, imparted by the vanes.

In the chamber this energy is partly converted into pressure energy a discharge pressure is imparted to the liquid. The energy transmitted from the pump motor, via the impeller, to the liquid is converted into kinetic energy and pressure energy.

| Specifications | ||||

| Model | Power (kw) | Max. Volume Rate (m3h) | Inlet & Outlet size | Max. Head (m) |

| BM-5 | 0.75 | 1.5t | 1.5"/1.5" | 10 |

| BM-5 | 1.1 | 3t | 1.5"/1.5" | 15 |

| BM-5 | 1.5 | 6 | 2"/1.5" | 20 |

| BM-10 | 2.2 | 10 | 2"/1.5" | 15 |

| BM-15 | 3 | 15 | 2.5"/2" | 20 |

| BM-15 | 4 | 20 | 2.5"/2" | 25 |

| BM-20 | 5.5 | 30 | 2.5"/2" | 25 |

| BM-20 | 7.5 | 40 | 2.5"/2" | 30 |

| BM-30 | 11 | 50 | 2.5"/2.5" | 30 |

| BM-30 | 15 | 60 | 3"/2.5" | 30 |

| BM-40 | 18.5 | 80 | 4"/3" | 40 |

| BM-40 | 22 | 100 | 4"/3" | 40 |

| BM-40 | 30 | 120 | 4"/3" | 40 |