One of the most important requirements of modern dairying is to be able to control the temperature of products at every stage in the process.

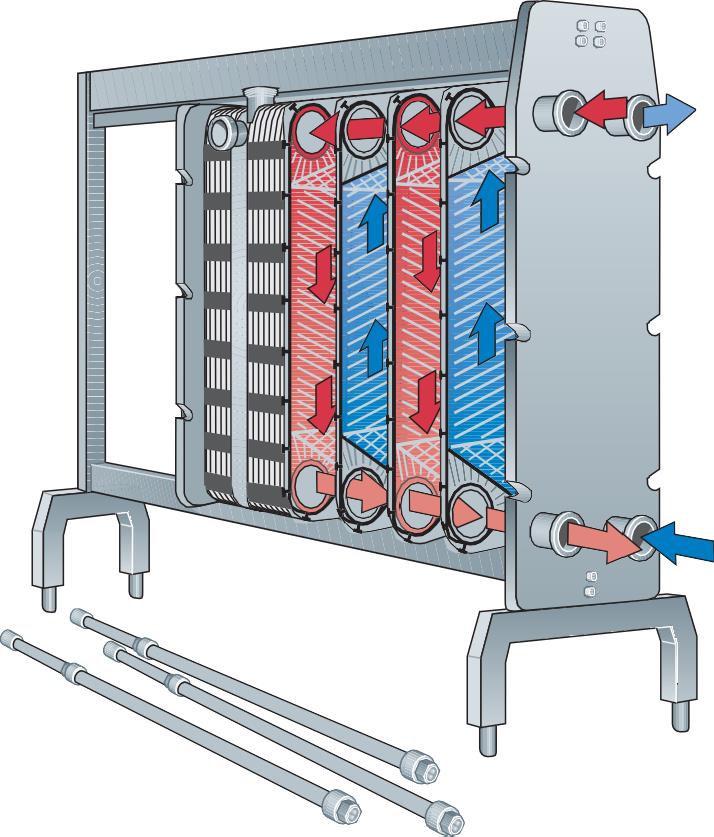

Heating and cooling are therefore very common operations in the dairy. Almost all heat treatment of dairy products is carried out in plate heat exchangers.

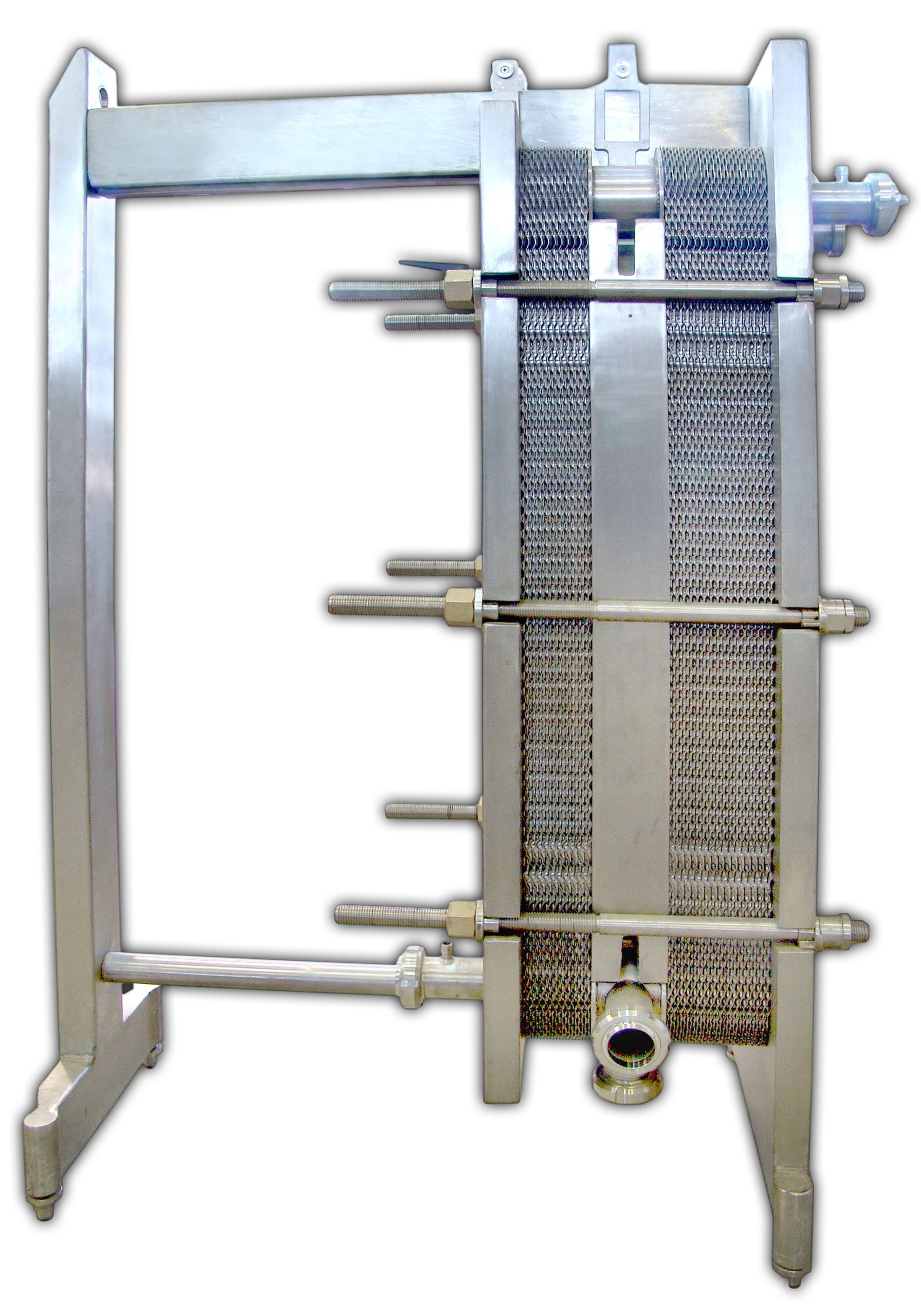

The plate heat exchanger (PHE) consists of a pack of stainless steel plates, clamped in a frame.

The frame may contain several separate packs-sections-in which different stages of treatment such as preheating, final heating, holding and cooling take place.

The heating medium may be vacuum steam or hot water, and the cooling medium cold water, ice-water or brine, depending on the required product outlet temperature.