Pasteurization of milk is one of the most important dairy processes.

Before it was Introduced, milk was a dangerous source of infection as it is a perfect growth medium for micro-organisms.

Its main aim is to destroy all pathogenic organisms, which cause disease in milk indeed. To achieve this milk has to be heated to a certain temperature and held at that temperature for a prescribed time.

The high temperature short time (HTST) method of pasteurization is used; The milk is heated to not less than 72°c, held at that temperature for at least 15 seconds and then rapidly cooled.

PASTEURIZERS

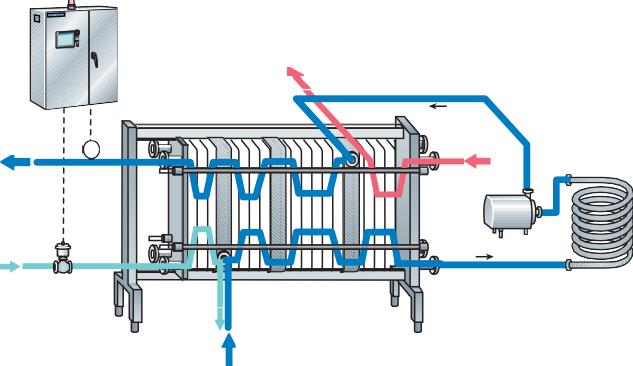

Milk comes from a silo tank to a balance tank and is pumped at a constant flow rate to the PHE. In the first section it is heated to pasteurization temperature.

The heated milk then flows through a holding section, where no temperature treatment is applied, in order to obtain the necessary holding time.

From the holding section the pasteurized milk continues to a cooling section where it is cooled to about +4°c.